Home > Notizie > Case studies > Panguaneta and Kiwitron: safety in plywood

Home > Notizie > Case studies > Panguaneta and Kiwitron: safety in plywood

Safety management in manufacturing plants is a current topic of great relevance for companies, with a view to continuous improvement and accountability.

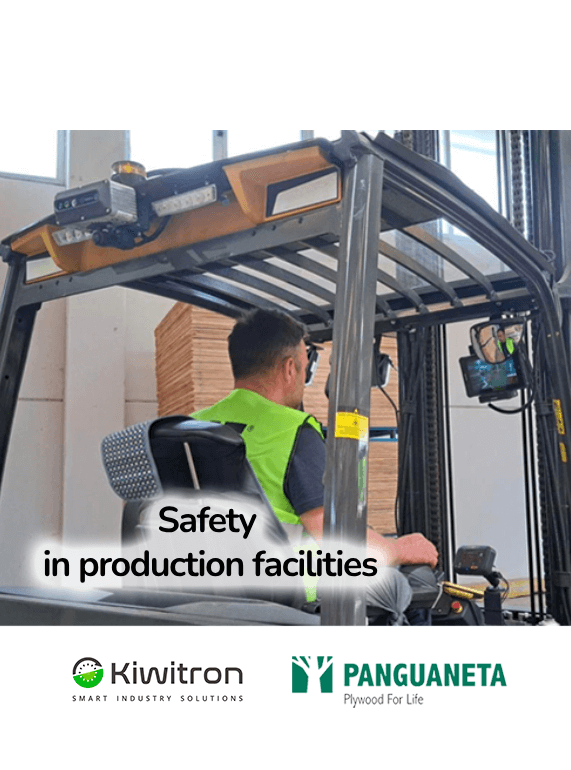

We had the opportunity to speak with Paolo Malatesta, an engineer in the plant and maintenance department of Panguaneta S.p.a. The company, an Italian excellence in the production of plywood-the plywood or multilayer panel-has recently adopted Kiwitron solutions in support of safety.

The result, according to Eng. Malatesta, is indisputable.

Our first requirement was about security.

Our vehicles move potentially dangerous goods and loads at high rates. At the same time, other vehicles, people, bicycles are circulating in the plant: we had an urgent need to solve the safety problem of our internal road system and maintain the same level of productivity.

We found ourselves needing to replace some forklifts at the end of their lifespan. We identified Caterpillar forklifts for the new purchase, on which we would later have to apply devices to increase safety.

CAT itself pointed us to Kiwitron solutions, based on our needs. In fact, we had a need for the safety aid system to fit all the different brands in our fleet.

The goal has been achieved: by installing your KiwiEye detection systems on eight of our trucks and two loaders, it has been possible to implement automatic slowing down only when vehicles and people are detected, increase driver visibility and solve the problem of blind spots.

In the face of no decrease in productivity! We can be completely satisfied.

Panguaneta is a leading manufacturer of plywood, the plywood and multilayer wood panel.

Historically and due to the nature of our area, we are very closely related to poplar, from which most of our veneers, which make up the panels, are made. Panel production activity goes through the stages of composition, pressing, squaring, sanding and storage.

In-house handling, especially in the areas where we have applied the optical sensor with KiwiEye artificial intelligence, involves line-side transfers of veneer pallets.

This is where the process of making the panel begins. It involves heavy load handling.

On the other hand, we also use vehicles equipped with KiwiEye on the yard of the production plant, so outdoors. This is where logs are unloaded from the trucks, lined up and brought with shovels to the line feed.

The outdoor spaces are large, but the severe ones the trucks are loaded with are dangerous. The magnitude of an impact, if this were to occur, would undoubtedly be very high.

Different carts are assigned and entrusted for management to each department. For unplanned downtime and any maintenance, extraordinary or scheduled, we also have some “wild card” carts available. The high pace of production pushes us to make full use of our resources.

KiwiEyes can be connected to a screen to provide full visibility to the driver in the maneuvering area, and are connected to the KeyTouch datalogger.

Integration with the datalogger is proving particularly useful for the usability of the data we are interested in.

In particular, due to continuous and tight shifts, the KeyTouch datalogger has become an invaluable tool for monitoring the history of the trucks and for damage analysis, which is possible due to the recording of impacts.

The visualization on the damage management helps us to understand how and when an event was generated, and if necessary to intervene with ad hoc maintenance.

The history of the truck at work now becomes traceable. This allows procedures to be formulated to define the status of the machine at each handover between operators, somewhat as is done for rentals.

Certainly. Data is not only used to monitor the company’s activities, but also-and this is even more important to us-to create a certain corporate culture, based on shared responsibility and security, awareness of the interconnectedness of operations, and cooperation.

It is not a matter of using data for micromanagement purposes, on the contrary: it is inevitable to incur damage or accidents from time to time, while it is essential to understand in detail how it happened in order to constantly increase the level of prevention.

From mistakes we can learn, and data can be key indicators for learning. If prevention is integrated into business life, operations can benefit as well: safely increasing productivity is among our future goals.