The Kiwitron solution to digitalize your fleet

Discover how to monitor, control, and optimize the use and maintenance of non-road mobile machinery (such as forklifts), improving overall management and productivity

Francesco Marella

Head of HSE Mitsubishi Electric Hydronics & IT Cooling System S.p.A.

The most sophisticated data loggers, like the KeyTouch with its screen, or the KiwiEye computer vision system for safety assistance, are Kiwitron’s top-of-the-line products that we recommend for achieving technological excellence

Ugo Turchetti

Managing Director di CGM CAT Lift Trucks

- Compatibility with all forklift brands

- Compliance with Industry 4.0 and 5.0 specifications

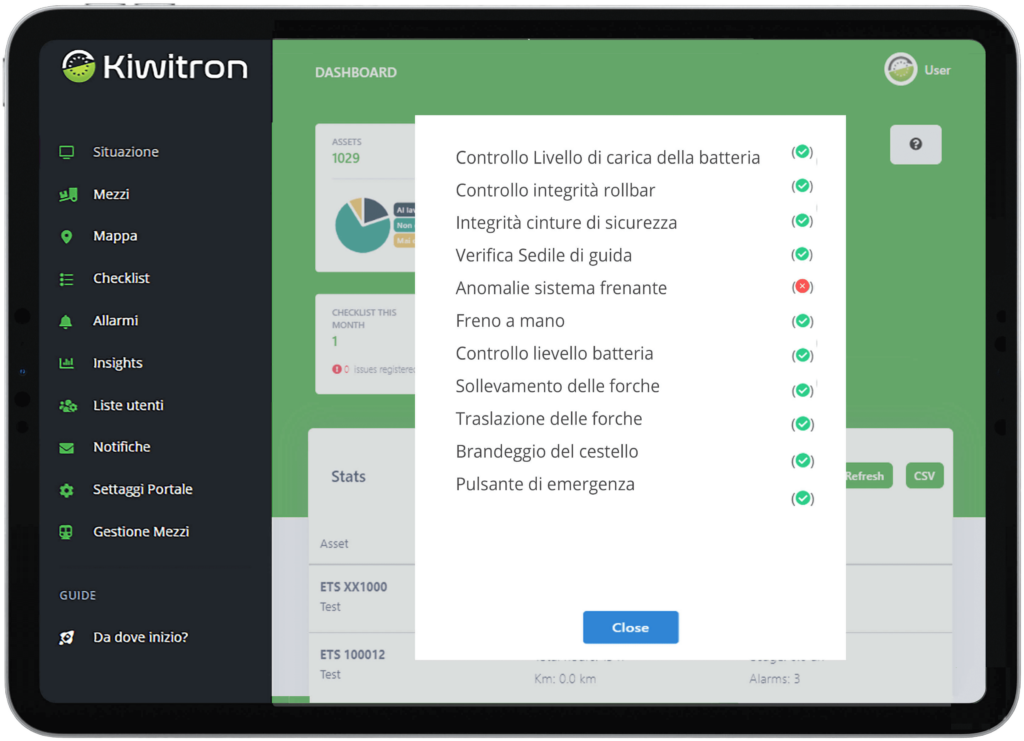

- Digital pre-operational checklists

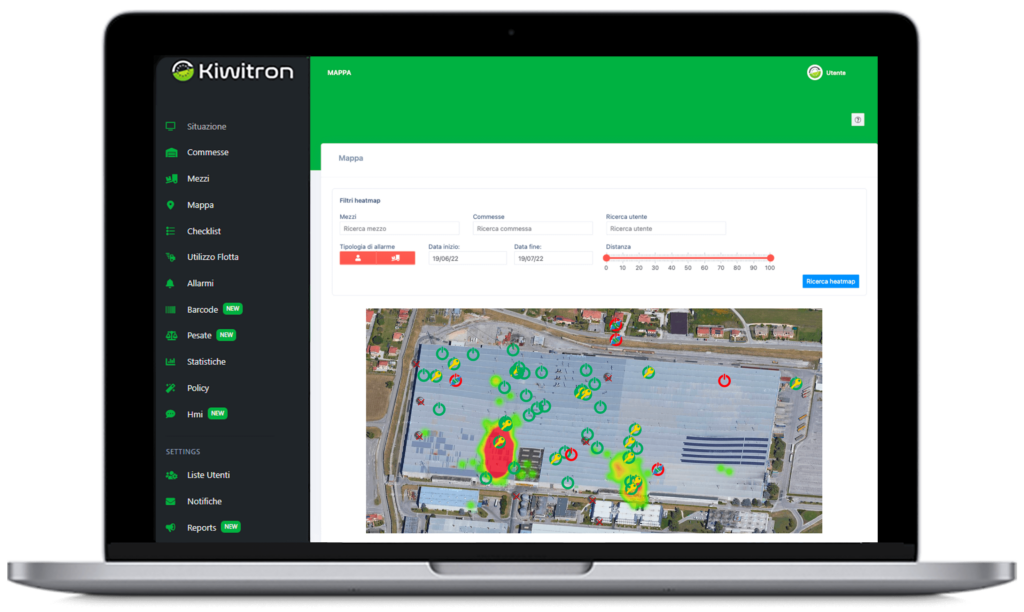

- Impact reporting, battery analysis, and localization

- Access control with RFID badges and PIN codes

KeyTouch for ISO 45001 certification

With KeyTouch, you can create pre-operational checklists specific to vehicle management: the RSPP or HSE can thus monitor that operations are conducted safely and according to the correct procedures.

KeyTouch recognizes and authorizes (via RFID badge or PIN code) the use of the vehicle only to qualified operators, also analyzing their driving style. This allows the differentiation of vehicle use between experienced and inexperienced operators.

KeyTouch also allows you to monitor the usage and efficiency of machines through ready-made reports and tools to plan maintenance, in order to reduce downtime and optimize productivity.

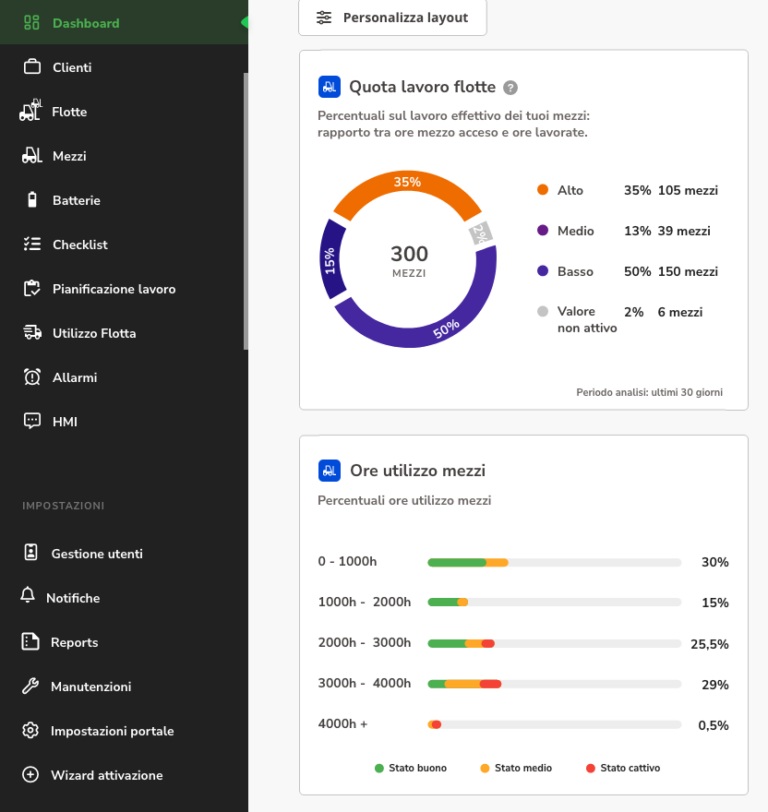

Maximize efficiency

When the machines are equipped with KeyTouch, you have the information needed to monitor the efficiency of your fleet, with reports dedicated to actual working hours and charts for the simultaneous use of machines.

These features allow you to optimize the allocation of vehicles and improve productivity, as you can better allocate resources, ensuring that each vehicle is used to its full capacity.

Additionally, by monitoring the actual use of the machines, you can identify and reduce waste, resulting in more economical fleet management.

Optimized maintenance for your forklifts

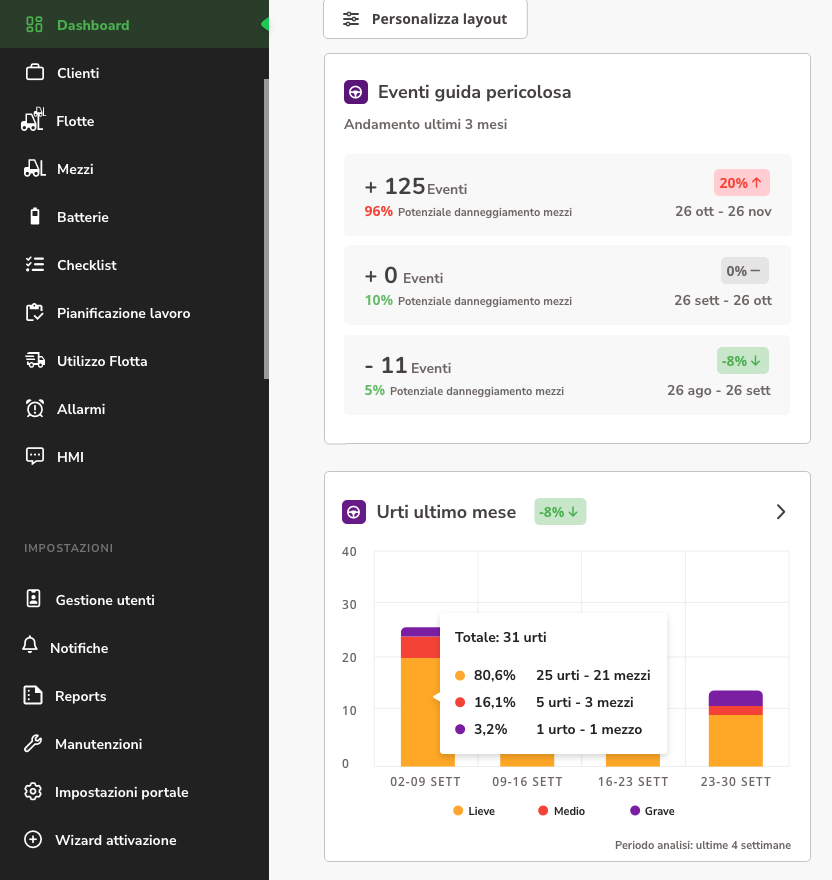

KeyTouch is equipped with sensors (GPRS/LTE locator – GPS/GNSS and accelerometer) used to send notifications of impacts via email or SMS, allowing real-time monitoring of accidents or issues related to the pavement.

In case of an impact, the vehicle can be set to automatically reduce its speed.

Through electrolyte and current sensors, KeyTouch monitors the electrolyte level and indicates incorrect battery usage, such as short charges.

With precise data on use and maintenance, you can schedule maintenance interventions more accurately, avoiding unexpected breakdowns and extending the service life of your vehicles. Thus, KeyTouch helps you save on costs associated with forklift maintenance and repair.

Through electrolyte and current sensors, KeyTouch monitors the electrolyte level and reports any incorrect battery usage, such as short charging.

With precise data on usage and maintenance, you can schedule maintenance interventions more accurately, avoiding unexpected breakdowns and extending the lifespan of your forklifts. Thus, KeyTouch helps you save on costs associated with forklift maintenance and repair.

Optimized maintenance for your forklifts

KeyTouch is equipped with sensors (GPRS/LTE locator – GPS/GNSS and accelerometer) used to send notifications of impacts via email or SMS, allowing real-time monitoring of accidents or issues related to the pavement.

In case of an impact, the vehicle can be set to automatically reduce its speed.

Agevolazioni fiscali con Industria 4.0 e 5.0

Il datalogger KeyTouch è compatibile coi requisiti di Industria 4.0 e del Piano Transizione 5.0, consente di eseguire l'analisi sull'efficienza delle macchine (elettriche e diesel) e permette un monitoraggio continuo dei parametri per verificare i reali consumi.

KeyTouch, connesso al gestionale in cloud KiwiSat, consente la telemanutenzione, la teleassistenza e l'attivazione delle funzionalità del mezzo da remoto.

Tutte le funzionalità di KeyTouch sono integrabili sul gestionale in tuo possesso in modo semplice e gratuito.

Seguiamo la parte burocratica insieme ai consulenti certificati per effettuare le perizie necessarie alla certificazione del sistema.

Maximize Return on Investment with KeyTouch

With KeyTouch, operators become more aware of how they use the machines. By avoiding harmful behaviors and making more efficient use of the battery, you can achieve significant cost savings in maintenance, increase fleet longevity, and enhance operational efficiency, thus ensuring a quick return on investment.

KeyTouch can be integrated with safety solutions to ensure even more efficient and secure operations

Our pedestrian and obstacle detection systems for industrial machines play an important role in risk prevention. These systems, integrated with KeyTouch, allow control over certain machine movement functions (e.g., speed).

KiwiEye

Machine-to-machine and machine-to-pedestrian detection system with artificial intelligence

UWB Anti-collision

Machine-to-machine and machine-to-pedestrian detection system with operator tags

With KeyTouch, you have the ideal solution for monitoring your fleet vehicles

KeyTouch easily integrates with mobile machines, such as pallet trucks, walk-behind trucks, lifting platforms, industrial cleaning machines, and forklifts. Of any brand.

Forklifts

Industrial cleaning vehicles

Other vehicles

Discover the Key range

KeyOne

Black box for data collection

- GPRS/LTE – GPS/GNSS localization

- Impact sensors

- Integration with safety systems and management software

- SIM data transmission

- Access control with iButton

- CAN bus/RS232 protocol

- Barcode scanning

KeyTouch

Datalogger with RFID and touch display

- GPRS/LTE – GPS/GNSS localization

- Impact sensors

- Integration with safety systems and management software

- Data transmission via SIM and Wi-Fi

- Access control with RFID badge and PIN code

- Pre-operational checklists

KeyAdvanced

Datalogger with RFID

- GPRS/LTE – GPS/GNSS localization

- Impact sensors

- Integration with safety systems and management software

- Data transmission via SIM and Wi-Fi

- Access control with RFID badge